click here for pdf link to Dual Installation Instructions

click here for pdf link to Dual Installation Instructions for ULTRA only |

click here for pdf link to 2014 RELAY Installation Instructions |

QUICK TIPS

(EXPANDED TIPS BELOW QUICK TIPS)

Make sure all screws on back of trumpets are there and that they are tight.

Inside of trumpet should be clean, dirt prevents diaphragm from vibrating and making sound. Remove the 10 screws (3 on Big and Little Big Horns) from back of trumpets and clean diaphragm and inside of trumpets. Be sure to blue Loc-Tite the screws when you put the covers back on the trumpets.

Check for kink or hole in the hose, this is an air horn, no air-no horn.

Hose should be on air fitting as far as possible.

Hose clamps should be tight, use our stainless hose clamps, nylon ties will expand with heat and let air escape, horn will not work without air, and you will burn out your compressor.

Compressor needs to be under horn cover, it needs to take in clean air to exhaust clean air into trumpets.

Do not modify our bracket.

Trumpets and horn cover with compressor underneath need to be on our black powder coated bracket for balance.

Relay must be used.

Check for corrosion on battery posts and connectors.

Battery needs full charge.

Use the polymer hose provided, the specs are ¼” ID X 12+/-” long. Do not use oil lines (1/2” ID), it will increase in the volume of air will be beyond the compressor’s capability and will quickly burn out compressor.

If no SOUND, or to make horns LOUDER:

Remove chrome air fitting with either a 5/8" or adjustable wrench. From Home Depot/Lowes/Ace, get a yellow roll of gas pipe teflon tape, (not blue/water roll), Wrap tape 2.5 times around threaded area. Re-install with 5/8" very tightly.

EXPANDED TIPS

BENCH TEST UNIT: If none of the above tips gets your horn working, take the horn and compressor off the bike, keep the hose between the compressor and trumpets attached, run wires from the bottom of compressor to a car or truck battery. If it works on a different system then there is something wrong with your bike’s wiring.

RELAY: You must use the relay. Do NOT use ground wire from your stock horn to your compressor. Use a 12 or 14 gauge automotive wire from the negative side of compressor to negative battery post. Leave some slack in the new wire for flex in the bike. Do NOT USE SPEAKER WIRE, TELEPHONE CORD, LAMP CORD..NOTHING MEANT FOR HOUSEHOLD USE!!

.

BATTERY: Another overlooked item that affects sound quality is the battery. Motorcycle batteries do not last 3 to 4 years. They can, but I would not want to take a cross-country trip in the middle of a HOT summer on anything older than one year. If your battery is low, our compressor will still work, but not enough to push enough air through our diaphragm. Bikes that sit lose charge, the colder it is, the faster they lose charge. Also, make sure battery terminals are cleaned at least once a year (sand paper or wire brush), this is a good tip for all bike functions!

A general rule of thumb about batteries - it takes 20% of your charge to start your bike, and a full 20 minutes of running time to recharge your battery.

MUST READ !! VERY IMPORTANT!!!

If you have an older bike with one hot wire for horn, you need to run a separate wire(12 or 14 gauge) from our ground (-) on compressor to ground side of battery. Do not use frame as ground, compressor must be properly grounded to battery.

Bottom of compressor is marked (+) positive and (-) negative ground. Red or pink goes to (+) and black goes to (-) ground.

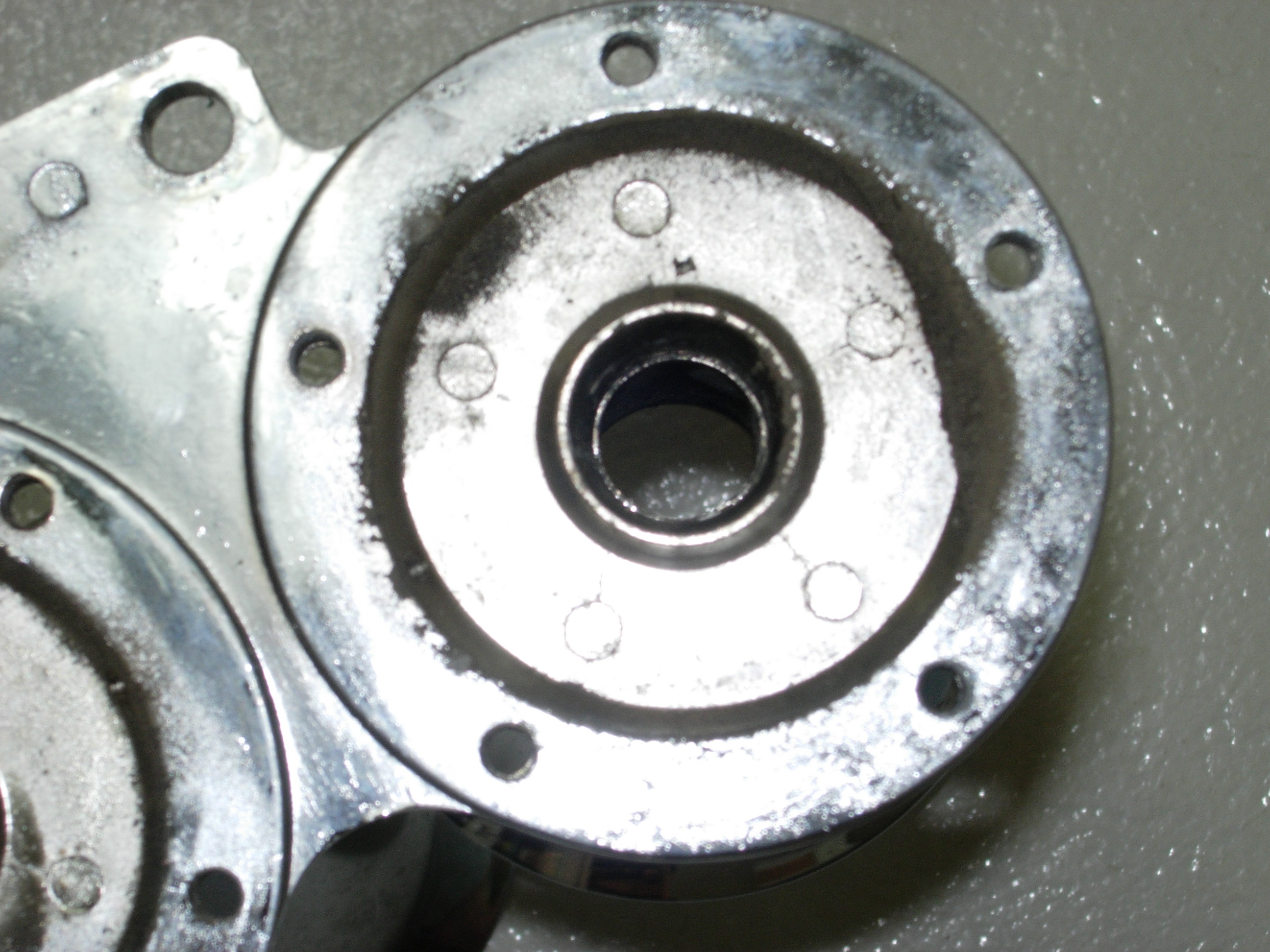

A clean battery cable connection to your battery will greatly improve your STARTING POWER, keep lights bright, and make your horn even louder. These pictures are a stock cable from a garaged 1997 Fatboy with 8,700 miles. As you can see, the last 2 inches of copper wire at each end of the cable is now corroded which prevents full transfer of electricity from the battery to the bike and accessories. This bike would randomly not start and we would have to remove the seat, and loosen, then re-tighten the nut holding the cable to the battery.(Please click on pictures to enlarge for detail.)

A clean battery cable connection to your battery will greatly improve your STARTING POWER, keep lights bright, and make your horn even louder. These pictures are a stock cable from a garaged 1997 Fatboy with 8,700 miles. As you can see, the last 2 inches of copper wire at each end of the cable is now corroded which prevents full transfer of electricity from the battery to the bike and accessories. This bike would randomly not start and we would have to remove the seat, and loosen, then re-tighten the nut holding the cable to the battery.(Please click on pictures to enlarge for detail.)

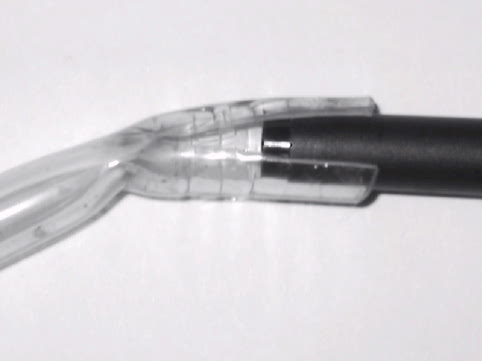

HOSE ATTACHMENT: The hose is hard to push on the air fittings, we have trimmed the nylon air fitting at an angle to help. You can use a pair of needle nose pliers to open the end of the hose, hose should fit at least 3/4 of the way on both air fittings or air will escape. As you can see in the photo on the left, this customer has pinched the air hose beyond the point of letting air pass through the hose, also in order to fit the hose on fitting the hose was sliced about 1.25" which would have let the air escape if it got past the kink in the hose, no air no horn.

HOSE ATTACHMENT: The hose is hard to push on the air fittings, we have trimmed the nylon air fitting at an angle to help. You can use a pair of needle nose pliers to open the end of the hose, hose should fit at least 3/4 of the way on both air fittings or air will escape. As you can see in the photo on the left, this customer has pinched the air hose beyond the point of letting air pass through the hose, also in order to fit the hose on fitting the hose was sliced about 1.25" which would have let the air escape if it got past the kink in the hose, no air no horn.

CLEANING INSIDE: Remove stainless screws (5 on each trumpet of duals, 3 on Big Horn and Little Big Horn) from back of trumpet and remove diaphragm. Note the black stuff (dirt)inside the back of the trumpet, click on pic to enlarge for detail. Clean recessed track with a spray-on light lubricant (not motor oil), we recommend WD-40. Clean both sides of diaphragm with lubricant by rubbing between index finger and thumb. After cleaning the track and diaphragm leave the lubricant on the track and diaphragm.

CLEANING INSIDE: Remove stainless screws (5 on each trumpet of duals, 3 on Big Horn and Little Big Horn) from back of trumpet and remove diaphragm. Note the black stuff (dirt)inside the back of the trumpet, click on pic to enlarge for detail. Clean recessed track with a spray-on light lubricant (not motor oil), we recommend WD-40. Clean both sides of diaphragm with lubricant by rubbing between index finger and thumb. After cleaning the track and diaphragm leave the lubricant on the track and diaphragm.

(On Little Big Horn and Big Horn if you detect a slight burr on diaphragm, make certain that the burr is toward the rear of trumpet (remember-burr to the back) when you put the diaphragm back into trumpet!)

After cleaning inside trumpetsand the diaphragms, re-install end caps and screws with a 2" screwdriver.

>

If we can be of further assistance please email us, we would enjoy hearing how much you love our product, we can be reached through the email address at this website.

Business hours are 9:00am to 4:00pm Eastern Time. Page updated 4/21/14

770-992-0034

OUR BUSINESS IS HONKIN' !!!!!

For technical support please send E-mail to TechSupport@howardshorns.com.

For technical support please send E-mail to TechSupport@howardshorns.com.Copyright © 1999 Howard's Horns